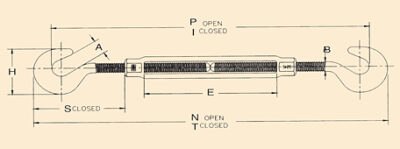

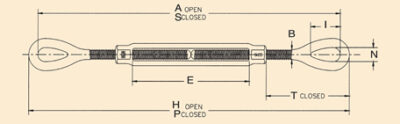

| Thread Diameter & Take Up (In) |

Thread Diameter &Take Up (mm) |

BTHH Item No. | Working Load Limit(t)* | Weight Each (kg) | Dimensions (mm) | ||||||||

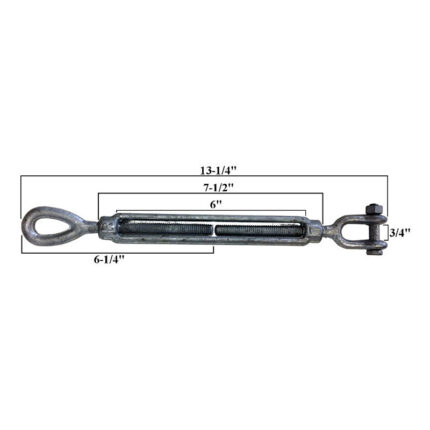

| B | A | S | H | P open |

I closed |

N open |

T closed |

E | |||||

| 1/4 x 4 | 6.35 x 102 | 15801 | 0.18 | 0.14 | 6.35 | 11.4 | 40.4 | 32.3 | 282 | 181 | 303 | 202 | 101 |

| 5/16 x 4.1/2 | 7.94 x 114 | 15802 | 0.32 | 0.21 | 7.85 | 12.7 | 49.3 | 38.1 | 325 | 211 | 351 | 236 | 114 |

| 3/8 x 6 | 9.53 x 152 | 15803 | 0.45 | 0.35 | 9.65 | 14.2 | 58.0 | 45.0 | 419 | 267 | 450 | 298 | 152 |

| 1/2 x 6 | 12.7 x 152 | 15804 | 0.68 | 0.73 | 12.7 | 16.8 | 74.5 | 58.0 | 478 | 300 | 518 | 340 | 152 |

| 1/2 x 12 | 12.7 x 305 | 15805 | 0.68 | 1.03 | 12.7 | 16.8 | 74.5 | 58.0 | 783 | 453 | 822 | 492 | 304 |

| 5/8 x 6 | 15.9 x 152 | 15806 | 1.02 | 1.25 | 16.0 | 18.9 | 93.5 | 71.5 | 521 | 337 | 572 | 387 | 152 |

| 5/8 x 12 | 15.9 x 305 | 15807 | 1.02 | 1.59 | 16.9 | 18.9 | 93.5 | 71.5 | 826 | 489 | 876 | 540 | 304 |

| 3/4 x 6 | 19.1 x 152 | 15808 | 1.36 | 1.76 | 19.1 | 24.9 | 115 | 84.5 | 568 | 378 | 629 | 439 | 152 |

| 3/4 x 12 | 19.1 x 305 | 15809 | 1.36 | 2.64 | 19.1 | 24.9 | 115 | 84.5 | 873 | 530 | 934 | 591 | 304 |

| 3/4 x 18 | 19.1 x 457 | 15810 | 1.36 | 3.68 | 19.1 | 24.9 | 115 | 84.5 | 878 | 683 | 1239 | 744 | 457 |

| 7/8 x 12 | 22.2 x 305 | 15811 | 1.81 | 3.67 | 22.4 | 28.7 | 132 | 96.0 | 914 | 565 | 984 | 635 | 304 |

| 1 x 12 | 25.4 x 305 | 15812 | 2.27 | 5.41 | 25.4 | 31.8 | 148 | 108 | 956 | 600 | 1034 | 678 | 304 |

| 1 x 18 | 25.4 x 457 | 15813 | 2.27 | 6.35 | 25.4 | 31.8 | 148 | 108 | 1261 | 753 | 1338 | 830 | 457 |

| 1 x 24 | 25.4 x 610 | 15814 | 2.27 | 7.82 | 25.4 | 31.8 | 148 | 108 | 1565 | 905 | 1643 | 983 | 609 |

| 1-1/4 x 12 | 31.8 x 305 | 15815 | 2.95 | 8.62 | 31.8 | 38.1 | 183 | 130 | 1027 | 659 | 1119 | 751 | 304 |

| 1-1/4 x 18 | 31.8 x 457 | 15816 | 2.95 | 9.33 | 31.8 | 38.1 | 183 | 130 | 1332 | 811 | 1424 | 903 | 457 |

| 1-1/4 x 24 | 31.8 x 610 | 15817 | 2.95 | 10.4 | 31.8 | 38.1 | 183 | 130 | 1637 | 964 | 1729 | 1056 | 609 |

| 1-1/2 x 12 | 38.1 x 305 | 15818 | 3.40 | 12.2 | 38.1 | 47.8 | 212 | 146 | 1116 | 735 | 1205 | 824 | 304 |

| 1-1/2 x 18 | 38.1 x 457 | 15819 | 3.40 | 14.1 | 38.1 | 47.8 | 212 | 146 | 1421 | 887 | 1510 | 976 | 457 |

| 1-1/2 x 24 | 38.1 x 610 | 15820 | 3.40 | 17.0 | 38.1 | 47.8 | 212 | 146 | 1726 | 1040 | 1815 | 1129 | 609 |

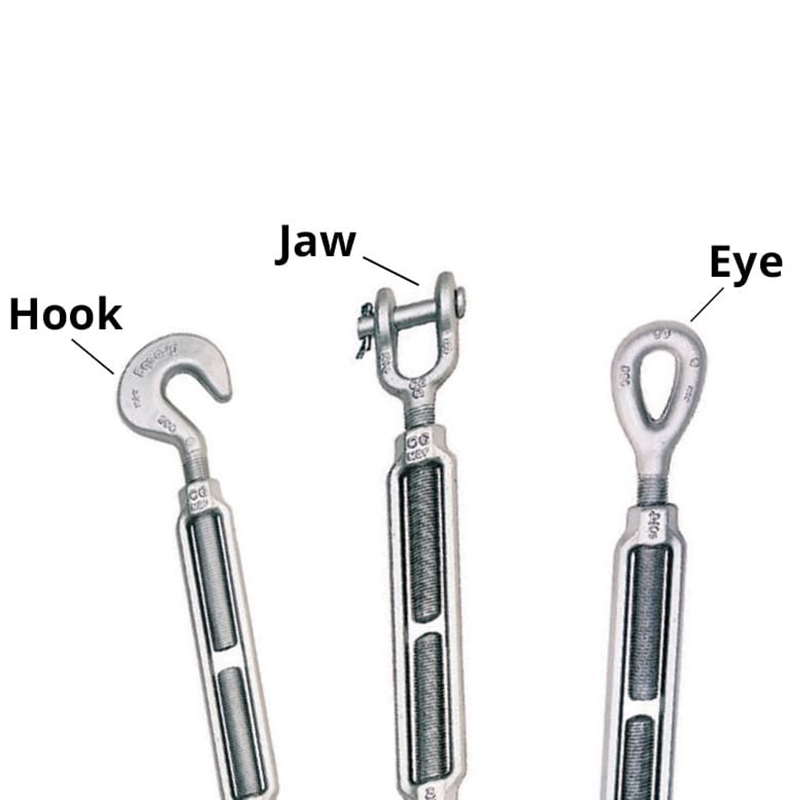

Turnbuckle with Hook-Hook End Fitting

- Hot Dip galvanized steel.

- End fittings are Quenched and Tempered / bodies heat treated by normalizing.

- Hooks are forged with a greater cross sectional area that results in a stronger hook with better fatigue properties.

- Lock Nuts available for all sizes

- BTHH-158 Hook & Hook Turnbuckle meets the performance of Federal Specifications FF-T-791b, Type 1, Form 1 – Class VI and ASTM F-1145.

- TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY

Product successfully added to the Quote List

Description

Features

Hook-and-hook turnbuckle for adjusting the tension and length of steel wires, cables and ropes

- Zinc electroplated surface for enhanced corrosion resistance

- Consists of two roll threaded forged steel jaws

- Made of low carbon steel

- Two welded hook terminals are screwed into each end of a forged steel frame

- Manufactured in accordance with DIN 1480

Applications

Storage and transportation

Roads and bridges

Steel structures

Wooden constructions

Related products

Cargo Lashing Belt

Master link assembly

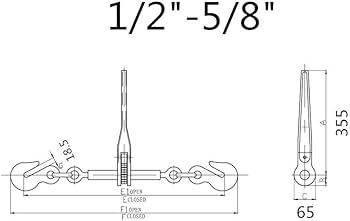

Ratchet loadbinder

Crosby Standard Lever Type Load Binders.

- Extra heavy construction at leverage point to prevent spreading. Heel of binder toggles away from load, permitting easy release.

- Ball and socket swivel joints at hook assemblies permit a straight line pull.

- Binders shown with Proof Loads have been individually proof tested to values shown, prior to shipment.

- Meets or exceeds requirements of US DOT FMCSA Part 393 Subpart I.

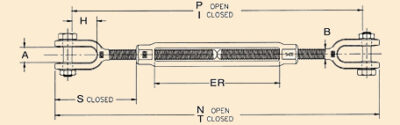

Turnbuckle with Eye-Eye End Fitting

- Hot Dip galvanized steel.

- End fittings are Quenched and Tempered / bodies heat treated by normalizing.

- Turnbuckles eyes are forged and elongated by design, to maximize easy attachment in system and minimize stress in the eye

- Lock Nuts available for all sizes

- BTEE-160 Eye & Eye Turnbuckle meets the performance of Federal Specifications FF-T-791b, Type 1, Form 1 -Class IV and ASTM F-1145.

- TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY

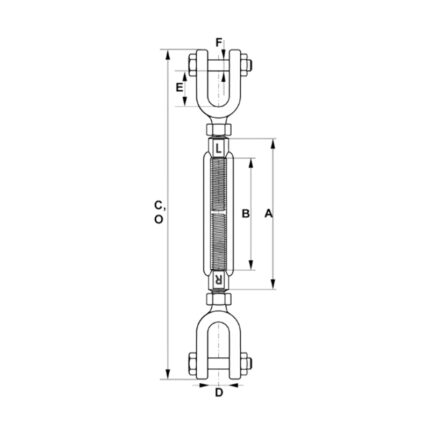

Turnbuckle with Jaw-Eye End Fitting

- Hot Dip galvanized steel.

- End fittings are Quenched and Tempered /bodies heat treated by normalizing.

- Lock Nuts available for all sizes

- BTJJ-162 Jaw & Jaw Turnbuckle meets the performance of Federal Specifications FF-T-791 b, Type1, Form 1 - CIassVII and ASTM F-1145.

- TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY

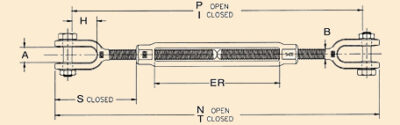

Turnbuckle with Jaw-Jaw End Fitting

Hot Dip galvanized steel.

End fittings are Quenched and Tempered / bodies heat treated by normalizing.

Lock Nuts available for all sizes

BTJJ-162 Jaw & Jaw Turnbuckle meets the performance of Federal Specifications FF-T-791b, Type 1, Form 1 - Class VII and ASTM F-1145.

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY

Vertical lifting clamp (LC)

The Toyolift Vertical lifting clamps provides a vertical transportation of plate sections. Attachment and removal of the clamps from the plate is extremely easy due to the simple and straightforward design.

Lifting Hooks provide a fast and efficient method for lifting plate or any similarly shaped fabrications. Compact shape and relatively low unit weight with high lifting W.L.L. It can only be used in pairs using a two-leg sling or spreader beam.

Vertical Lifting Clamp (VC)

The Toyolift Vertical lifting clamps provides a vertical transportation of plate sections. Attachment and removal of the clamps from the plate is extremely easy due to the simple and straightforward design. Lifting Hooks provide a fast and efficient method for lifting plate or any similarly shaped fabrications. Compact shape and relatively low unit weight with high lifting W.L.L. It can only be used in pairs using a two-leg sling or spreader beam.

Established on 2015

Want to know more about our products?

Leave us a message on WhatsApp or send us an e-mail and we will contact you shortly

Ropes

Ropes

Shackles and hooks

Shackles and hooks

Polyester Slings

Polyester Slings

Hoisting

Hoisting

Lifting tools

Lifting tools