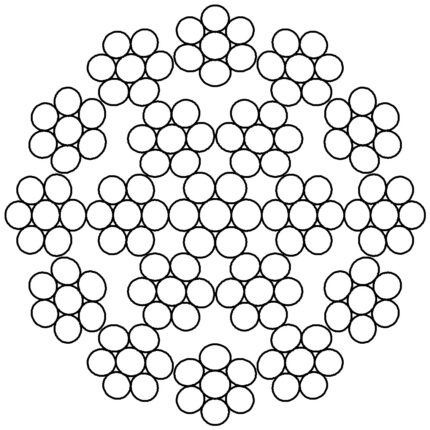

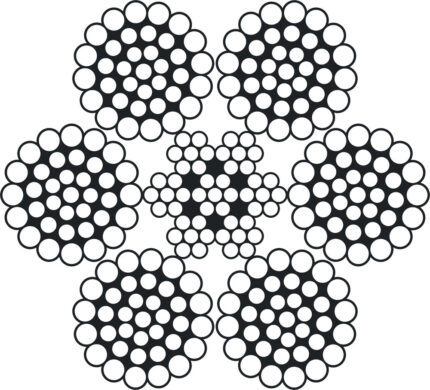

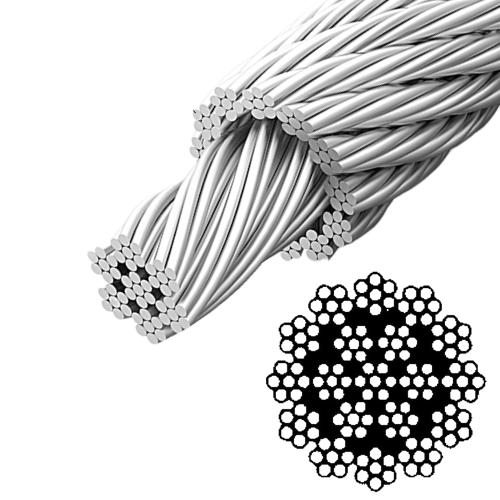

19*7

6x19 construction wire rope is available with either FC (fibre core) or WSC (wire strand core). When supplied with a wsc the rope is more commonly referred to as 7x19. The rope is very popular in diameters from 3mm to 16mm and is used on a variety of applications. 6x19 FC and 6x19 WSC (7x19) is very flexible in diameters 3mm to 6mm and is used for many requirements where wire ropes are running over pulleys. 7x19 construction is readily available in both galvanised and marine grade stainless steel.

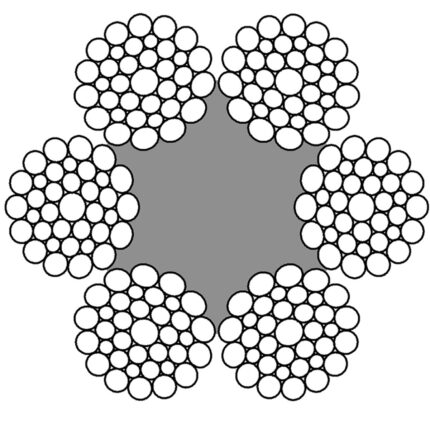

6*19 FC

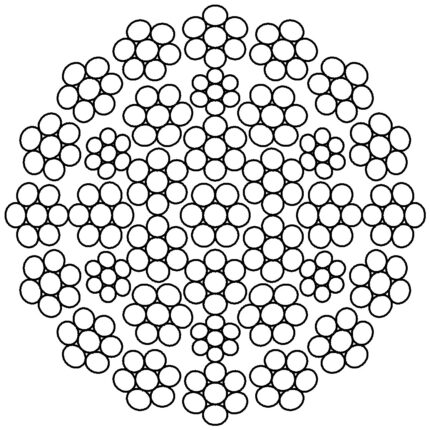

6x19 filler (often referred to as 6x25) is available with both FC (fibre core) and IWRC (independent wire rope core). With a fibre core, and due to the smaller wires used within the construction, 6x19 filler will generally achieve a superior fatigue life to the other 6x19 constructions. 6x19 filler wire rope has been a very popular construction for producing wire rope slings from 1 tonne safe working load up to 5 tonnes. One very good example is the high volume use of this construction in the North Sea Oil industry where it is used for the production of pipeslings.

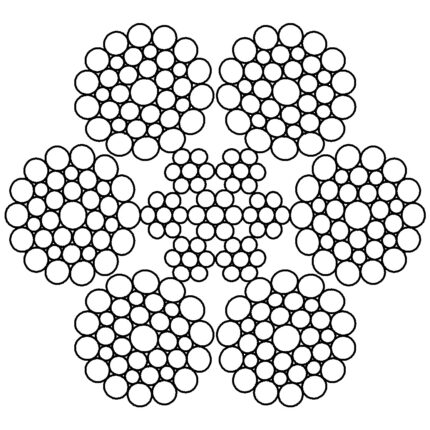

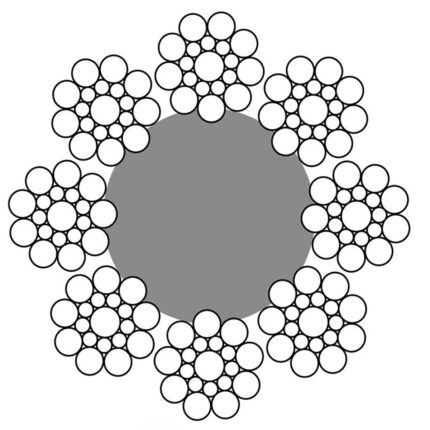

6*36 iwrc

6x36 is a flexible general engineering wire rope readily available in galvanised, ungalvanised and marine grade stainless steel. The wire rope has an equal lay construction (warrington seale) and achieves a superior breaking load to the 6x19 construction range. The construction has been designed to give a flexible rope with a good fatigue life. A 6x36 wire rope is available with either FC (fibre core) or IWRC (independent wire rope core) and is used for a wide range of applications, examples of which are shown below:

6×36-FC

6x36 is a flexible general engineering wire rope readily available in galvanised, ungalvanised and marine grade stainless steel. The wire rope has an equal lay construction (warrington seale) and achieves a superior breaking load to the 6x19 construction range. The construction has been designed to give a flexible rope with a good fatigue life. A 6x36 wire rope is available with either FC (fibre core) or IWRC (independent wire rope core) and is used for a wide range of applications, examples of which are shown below:

NYLON ROPE-3 STRAND

Manufactured by Miami Cordage up to 1-1/4″ diameter according to the Cordage Institute Standards, our 3-strand nylon twist rope consists of three equally sized strands of nylon fibers that are twisted together to produce a very strong rope with superb elasticity. Using premium high-tensile U.S. & European manufactured nylon fibers, we produce a durable rope through a four stage, balanced construction process. It handles great in both wet and dry conditions and will knot and splice easily.

POLYPROPYLENE ROPE-3 STRAND & 8 STRAND

Lam Hong carries a wide range of Polypropylene rope (PP rope). PP rope is a general-purpose rope, suitable for various applications. It has a density of 0.91 meaning this is a floating rope. PP rope is generally manufactured using mono-filament, split film or multi-filament fibres.

Commonly used for fishing and other general marine applications, it comes in a 3 and 4 strand construction and as an 8 strand braided hawser rope with a variety of colours. The melting point of polypropylene is 165°C.

Ropes

Ropes

Shackles and hooks

Shackles and hooks

Polyester Slings

Polyester Slings

Hoisting

Hoisting

Lifting tools

Lifting tools