- Capacities 0.3 to 55 metric tons, grade 6.

- Forged – Quenched and Tempered, with alloy pins.

- Working Load Limit and grade “6” permanently shown on every shackle.

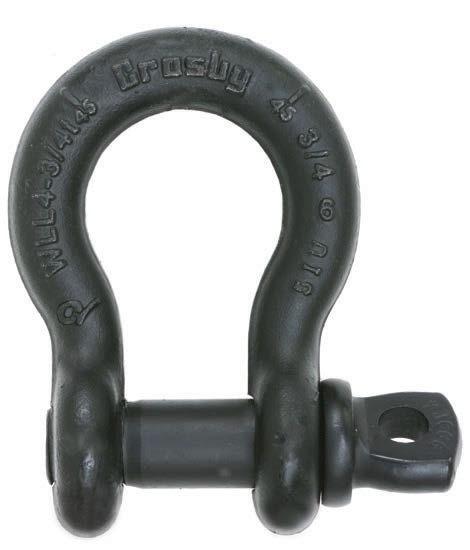

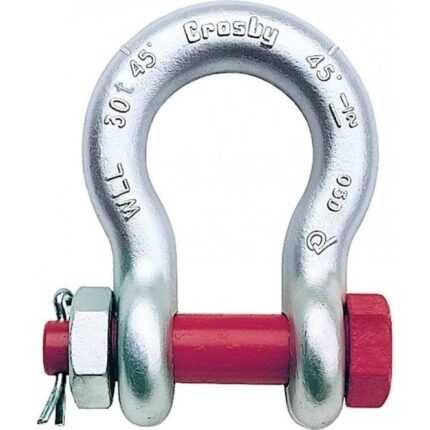

- Hot Dip galvanized or self colored.

- Fatigue rated.

- Shackles 25t and larger are RFID EQUIPPED.

- Shackles can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certification. Proof testing and certification available when requested at the time of order, charges will apply.

- Approved for use at -40 degrees C (-40 degrees F) to 204 degrees C (400 degrees F).

- All G209 shackles can meet charpy requirements of 42 joules(31 ft-lbs) avg. at -20 degrees C (-4 degrees F) upon special request.

- Meets or exceeds all requirements of ASME B30.26.

- Type Approval certification in accordance with ABS 2007 Steel Vessel Rules 1-11-17.7and ABS Guide for Certification on Cranes available. Certificates available when requested at time of order and may include additional charges.

Bow Shackle Screw Pin

G-210 Screw pin anchor shackles meet the performance requirements of Federal Specification RR-C-271F Type IVA, Grade A, Class 2, except for those provisions required of the contractor.

Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load Limit. For Working Load

Limit reduction due to side loading applications, see page 94 (‘Downloads’ tab above).

| Brand |

Grosby |

|---|

Product successfully added to the Quote List

The Crosby Group is a global leader in lifting, rigging, and material handling solutions. Founded in 1836, the company is known for manufacturing high-quality products such as shackles, hooks, wire rope clips, and load binders, primarily used in construction, oil and gas, maritime, and other heavy industrial sectors.

The Crosby Group is a global leader in lifting, rigging, and material handling solutions. Founded in 1836, the company is known for manufacturing high-quality products such as shackles, hooks, wire rope clips, and load binders, primarily used in construction, oil and gas, maritime, and other heavy industrial sectors.

Headquartered in Richardson, Texas, USA, Crosby operates worldwide, offering a comprehensive range of lifting and rigging products designed for safety, reliability, and performance. The company is recognized for its engineering innovation, rigorous product testing, and adherence to industry standards. Crosby's products are widely used in critical applications where safety is paramount.

The Crosby Group also emphasizes training and education, offering rigging training courses to ensure that professionals in the industry are knowledgeable about safe lifting practices.

| Nominal Size (in.) | Working Load Limit (t)* | Stock No. G-210 | Weight Each (kg) | Dimensions (mm) | Tolerance +/- | ||||||||||

| A | B | C | D | E | F | G | K | L | M | G | A | ||||

| 1/4 | 1/2 | 1019150 | .05 | 11.9 | 7.85 | 6.35 | 6.35 | 24.6 | 15.5 | 22.4 | 40.4 | 4.85 | 35.1 | 1.50 | 1.50 |

| 5/16 | 3/4 | 1019178 | .08 | 13.5 | 9.65 | 7.85 | 7.85 | 29.5 | 19.1 | 26.2 | 48.5 | 5.60 | 42.2 | 1.50 | 1.50 |

| 3/8 | 1 | 1019196 | .13 | 16.8 | 11.2 | 9.65 | 9.65 | 35.8 | 23.1 | 31.8 | 58.5 | 6.35 | 51.5 | 3.30 | 1.50 |

| 7/16 | 1-1/2 | 1019212 | .20 | 19.1 | 12.7 | 11.2 | 11.2 | 41.4 | 26.9 | 36.6 | 67.5 | 7.85 | 60.5 | 3.30 | 1.50 |

| 1/2 | 2 | 1019230 | .27 | 20.6 | 16.0 | 12.7 | 12.7 | 46.0 | 30.2 | 41.4 | 77.0 | 9.65 | 68.5 | 3.30 | 1.50 |

| 5/8 | 3-1/4 | 1019258 | .57 | 26.9 | 19.1 | 15.7 | 16.0 | 58.5 | 38.1 | 51.0 | 95.5 | 11.2 | 85.0 | 3.30 | 1.50 |

| 3/4 | 4-3/4 | 1019276 | 1.20 | 31.8 | 22.4 | 20.6 | 19.1 | 70.0 | 46.0 | 60.5 | 115 | 12.7 | 101 | 6.35 | 1.50 |

| 7/8 | 6-1/2 | 1019294 | 1.43 | 36.6 | 25.4 | 24.6 | 22.4 | 81.0 | 53.0 | 71.5 | 135 | 12.7 | 114 | 6.35 | 1.50 |

| 1 | 8-1/2 | 1019310 | 2.15 | 42.9 | 28.7 | 25.4 | 25.4 | 93.5 | 60.5 | 81.0 | 151 | 14.2 | 129 | 6.35 | 1.50 |

| 1-1/8 | 9-1/2 | 1019338 | 3.06 | 46.0 | 31.8 | 31.8 | 28.7 | 103 | 68.5 | 91.0 | 172 | 16.0 | 142 | 6.35 | 1.50 |

| 1-1/4 | 12 | 1019356 | 4.11 | 51.5 | 35.1 | 35.1 | 31.8 | 115 | 76.0 | 100 | 191 | 17.5 | 156 | 6.35 | 3.30 |

| 1-3/8 | 13-1/2 | 1019374 | 5.28 | 57.0 | 38.1 | 38.1 | 35.1 | 127 | 84.0 | 111 | 210 | 19.1 | 174 | 6.35 | 3.30 |

| 1-1/2 | 17 | 1019392 | 7.23 | 60.5 | 41.4 | 41.1 | 38.1 | 137 | 92.0 | 122 | 230 | 20.6 | 187 | 6.35 | 3.30 |

| 1-3/4 | 25 | 1019418 | 12.1 | 73.0 | 51.0 | 54.0 | 44.5 | 162 | 106 | 146 | 279 | 25.4 | 231 | 6.35 | 3.30 |

| 2 | 35 | 1019436 | 19.2 | 82.5 | 57.0 | 60.0 | 51.0 | 184 | 122 | 172 | 312 | 31.0 | 263 | 6.35 | 3.30 |

| 2-1/2 | 55 | 1019454 | 32.5 | 105 | 70.0 | 66.5 | 66.5 | 238 | 145 | 203 | 377 | 35.1 | 330 | 6.35 | 6.35 |

Related products

Bow Shackle Screw Pin

Clevis grab hook

Place of Origin: China

Brand Name: SLR

Certification: CE、GS

Model Number: SLR-123

Payment & Shipping Terms

Minimum Order Quantity: Material - Alloy Steel、 Size - Argument list、 Color - Red or OEM、 Surface finish - Powder Plastified、 Application - Heavy Industry,Water Treatment,Food & Bevel、 Production Method - BM、ODM、OEM

Clevis self locking hook

- Forged super alloy steel; Quenched & Tempered

- Suitable for EN812-2 G80 Chain

- 100% Magnaflux Crack Detection

- Individually proof-tested at 2.5X Working Load Limit

- Fatigue tested at 1.5X Working Load Limit for 20,000 cycles

- Surface Finish: Powder Plastified

- Positive lock latch is self-locked when hook is loaded

Dee Shackle Screw Pin

pipe hook

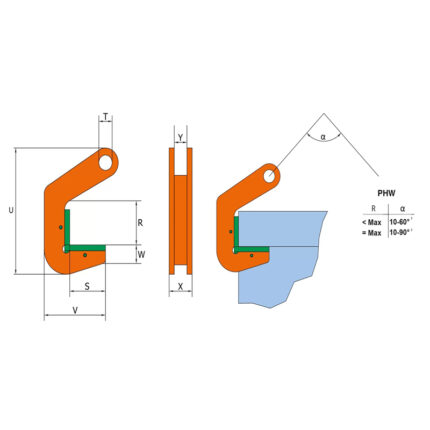

- Alloy steel plate construction.

- Equipped with a convenient handle.

- Equipped with a Bolt Type (Model G-2130) Shackle.

- Non marring inserts available.

- Used in pairs with 45° - 60° horizontal angle or 60° - 90° included angle Compact and lightweight in design..

- Teflon Pad replacements parts are available and easy to change

- Fitted with Screw pin bolt & Nut shackle

- Forged on Alloy steel plate

- Replacable Teflon pad inserts are fitted to reduce impact to edge of pipe and pipe threads

Swivel sling hook

Want to know more about our products?

Leave us a message on WhatsApp or send us an e-mail and we will contact you shortly

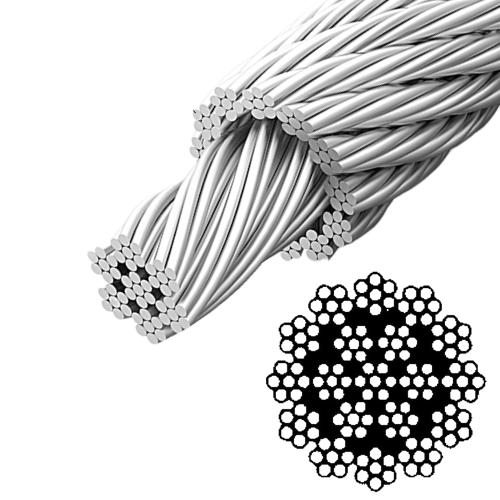

Ropes

Ropes

Shackles and hooks

Shackles and hooks

Polyester Slings

Polyester Slings

Hoisting

Hoisting

Lifting tools

Lifting tools